TechLab Tests

Only in Europe, every year, 6.5 billion € are wasted because of an improper use of packaging materials. An unstable pallet, not firmly held to the base, can constitute a difficult element to secure during the loading process. Costs come not only from the non-delivery, but they often come from additional returns to the manufacturer and from other problems linked to personnel that has to recover the damaged product, which is often thrown away to avoid even higher expenses. Our laboratory takes care of your product and works continuously to improve the transport future, reaching the optimisation of packaging and, at the same time, ensuring the best stability ever.

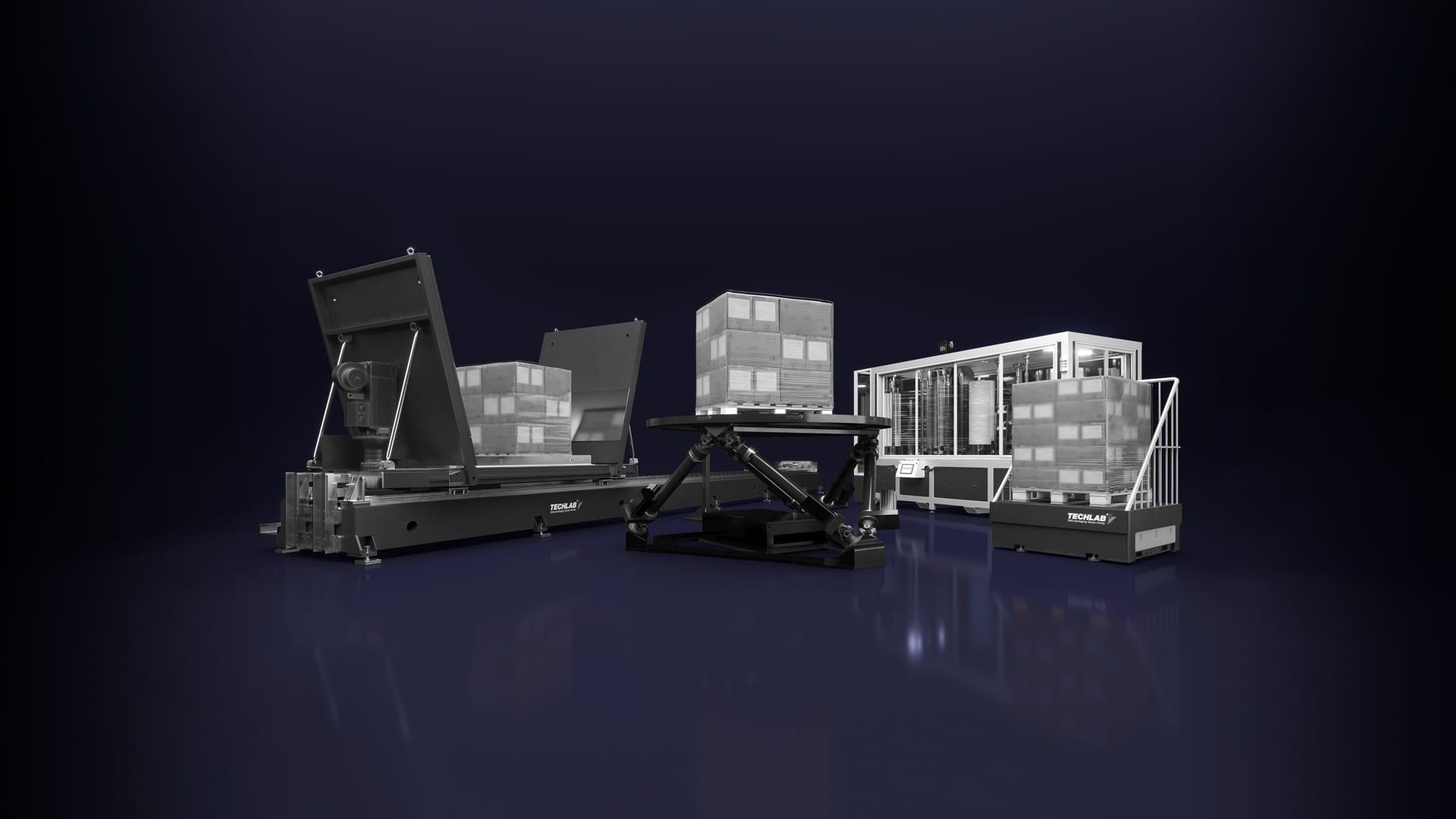

Accelerating sled

Thanks to our accelerating sled we are able to make different tests, simulating the worst case on every type of uneven path, whether it is by truck, train, sea or a mix of the three options.

Setting the correct stress we can assure that the product we are testing can face a determined path and come to destination without damages on their quality. Setting different measurement we can control how products react during the transportation and, analysing this reactions, we can understand strengths and weaknesses. Our instrumentation allows to immediately pursue comparative tests with different solutions, so that we can give results and optimisations in short time.

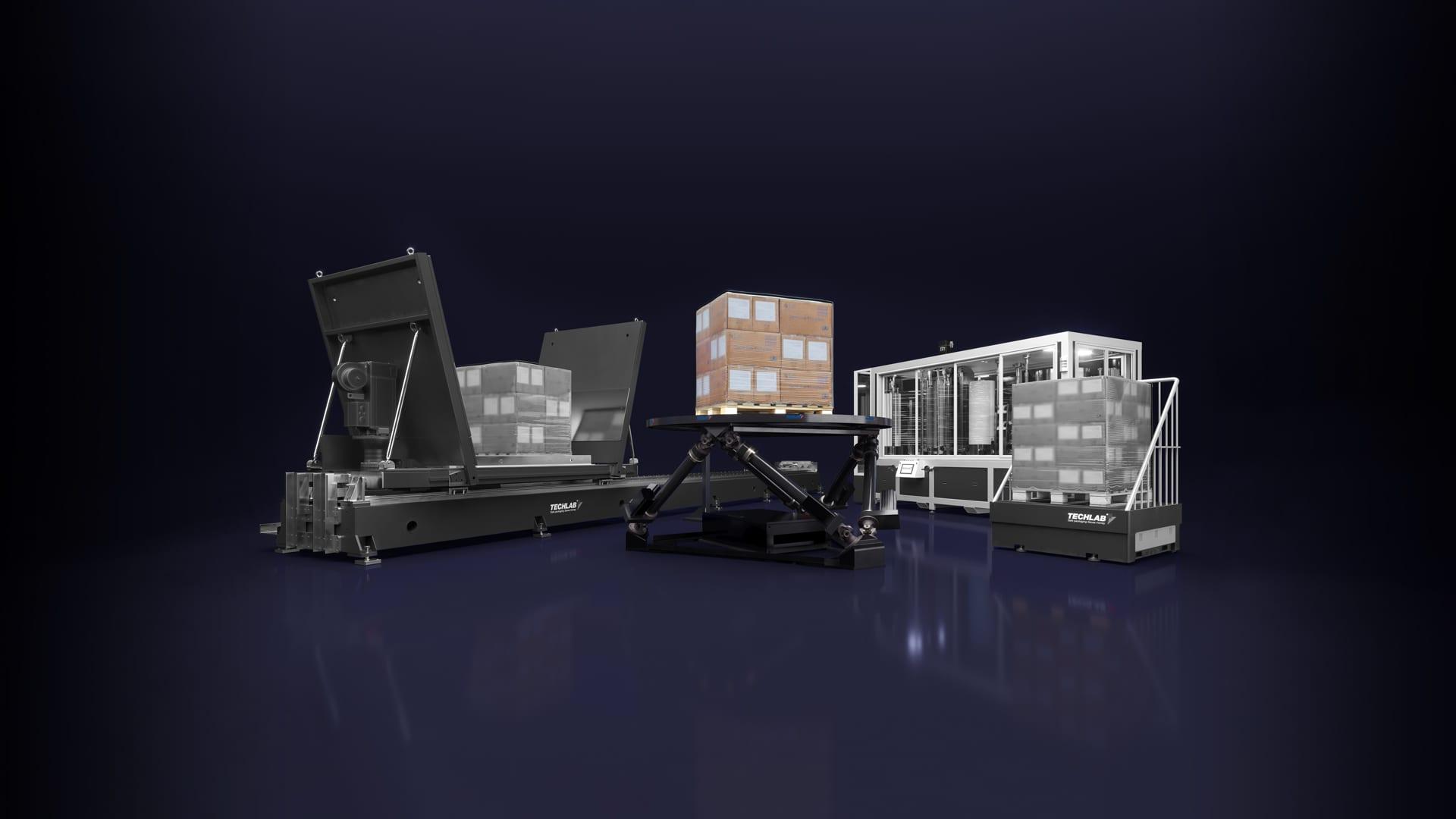

Shaking Table

The shaking table can test the pallet stability stressing the product by a circular movement around an axle.

Therefore, we can verify the product reactions while changing the test frequency and intensity, marking the weaknesses. The test is conducted following American regulations

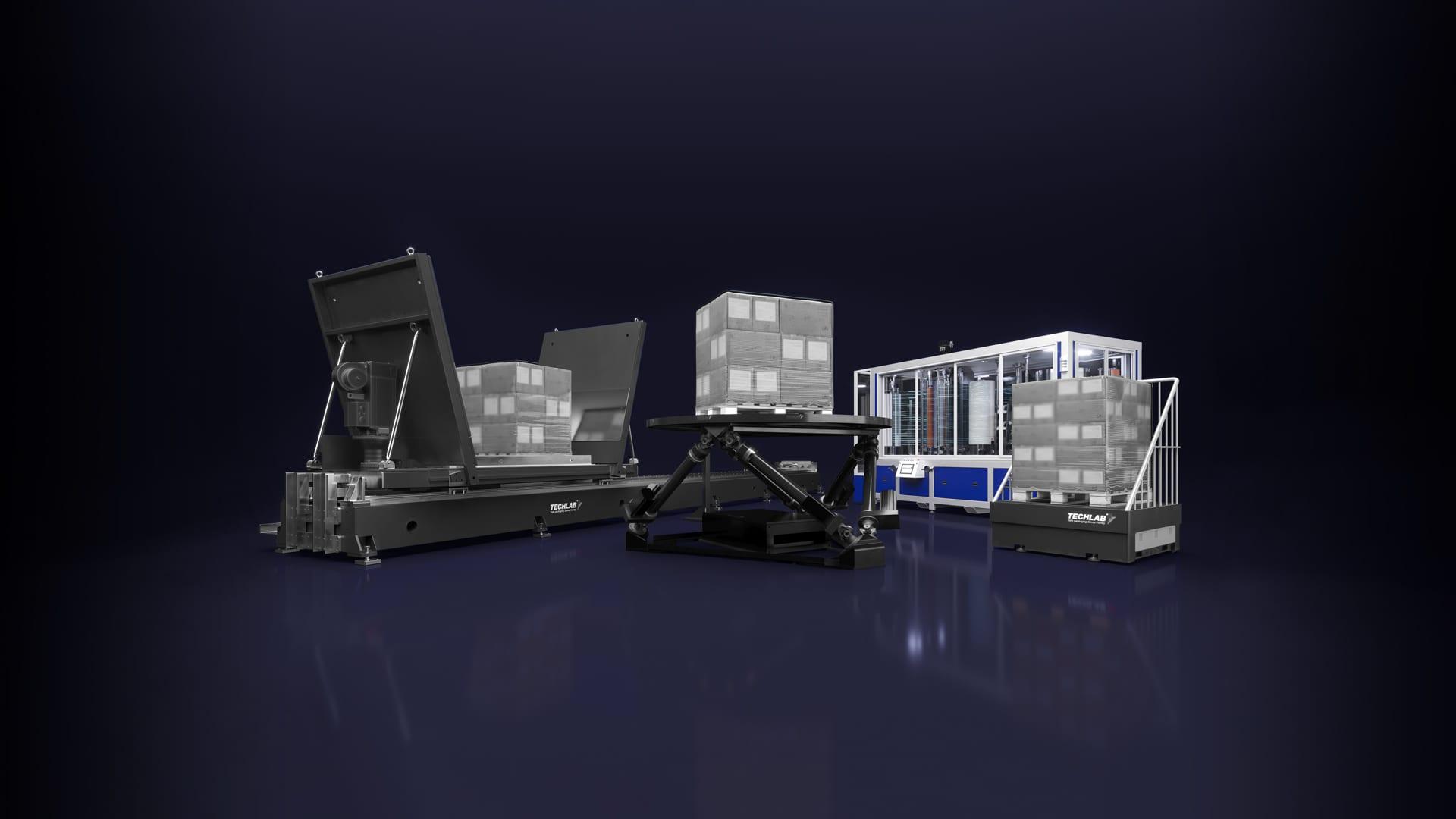

Hexapod

Techlab is the first Company that uses a machine which can accurately reproduce any type of transport. Hexapod can recreate each type of solicitation that can happen during the transport, in each of the 6 degrees of freedom; it can register an existing path, using an accelerometer, and reproduce it removing downtimes and solicitations that do not stress the sample.

Through these totally replicable tests we can recreate REAL transport conditions in very short time, comparing different solutions in a scientific approach. With the accurate reproduction of a transport, it is possible to check the reaction of every point of the pallet, analysing how every part of it interacts with the others and considering every possible damages.

Robotester

All the film reels belonging to this section have been tested, selected and checked by our experts, who have verified their behaviour optimising it for the customer's product. A real encyclopaedia on the behaviour of the film, with replicable scientific data that can be consulted at any time.

The multi-year experience of Techlab at your service!

A flexible layout permits to simulate every wrapping machine on the market.

Different type of tests can be performed:

- Quality test - analyses the film quality at a selected pre-stretch or stretch level detecting imperfections.

- Pre-stretch test – gives the mechanical behaviour graph of the film, through an incremental pre-stretch test.

- Puncture test – measures the perforation resistance of the film at a selected pre-stretch or stretch level according to ASTM D5748 standard.

- Stress Relaxation test – registers the film holding force and its reduction over time on a standard probe at a selected pre-stretch or stretch level.

- Tearing test – measures the tear propagation force of the film in transversal direction.

- Dart test – determines the film impact resistance

- Pallet stress relaxation test – measures the maximum load holding force and its reduction over time on the pallet, simulating real applications

- Cling test – measures the cling level of the film and its peeling force at a selected pre-stretch or stretch level.

- Cof test – provides the static and dynamic Coefficient Of Friction of the film on itself or on other surfaces.