Consultancy services

By working on the final solution, the whole pallet, we are able to have a behavioural feedback on all the components of the same pallet and we can optimise every single part, e.g. a can, a box, a palletisation scheme or even the cap of a bottle.

Our consultancy provides an accurate analysis of the current situation and the implementation of possible changes to increase the stability of the pallet. In addition to working on optimisation, we can offer training on how to work independently on continuous improvement of load stability, acting on wrapping recipes or on the implementation of palletising schemes, analysing how these two factors contribute to the solidity of the pallet.

Simply by changing the positioning of the products it is possible to considerably increase the stability of the pallet. In the study of the overall stability of the palletised load, the palletisation scheme is of great importance and it is optimised by our experts through best-fitting modelling.

The arrangement, the need and the size of any stiffening interlayer is scientifically assessed depending on the types of load units.

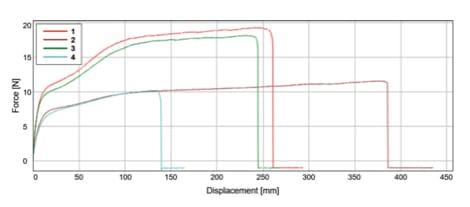

We test the resistance of the bundle to the movement of the containers, measuring the necessary force to move a batch of bottles with respect to the rest of the bundle.

Expected benefits

It is possible to scientifically verify the consistency of the package for logistic handling on pallets. A valuable help for testing its resistance when deciding to reduce the thickness of the film.

Applications

ROBOPAC and OCME packaging machines, for all market sectors.

A very important aspect is the characterisation of the shape and rigidity of the bottles which represent the structural base and the stability of the bundles, the layers and the entire palletised cluster. Characterisation is obtained with specific and dedicated instrumentation.

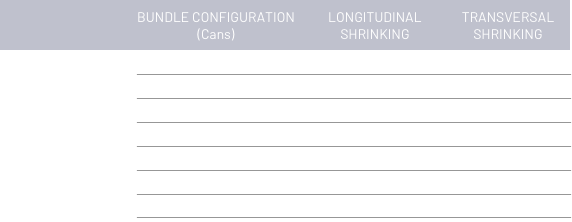

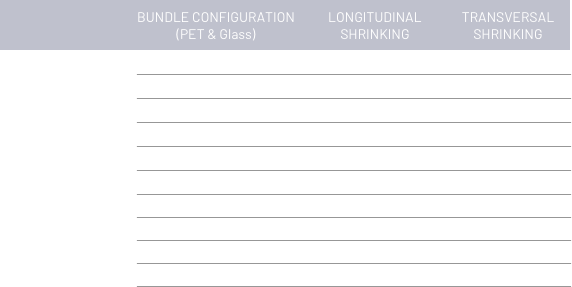

The longitudinal and in transverse shrinking reports of the film are measured by immersing the film in a temperature controlled oil bath .

Expected benefits

The knowledge of the shrinkage characteristics of the film are fundamental for the realisation of good quality bundles, in fact the longitudinal shrinkage report is closely linked to the rigidity of the bundle and to the depth of the hollows between the bottlenecks. The transverse retraction report, however, is more related to the aesthetic quality of the bundle: a higher value generally leads to fewer wrinkles in spite of a larger lateral opening.

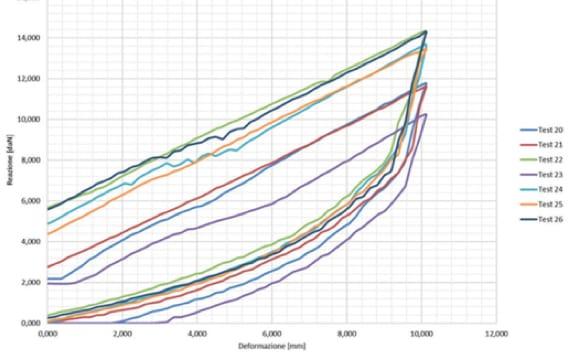

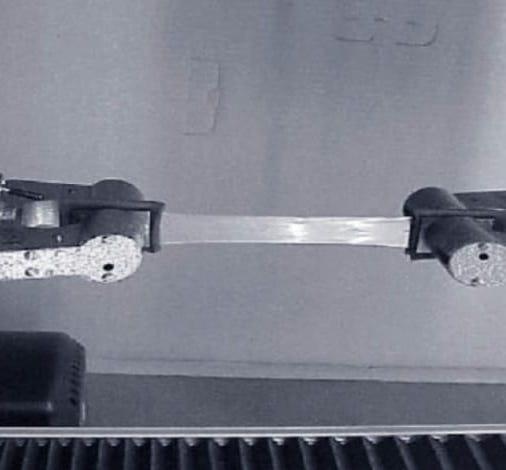

Film samples are stretched until they break. During deformation, a load cell records in real time the reaction that the specimen is opposing to the elongation.

Expected benefits

With this test, it is possible to fully characterise a material including its elastic range, Young's modulus, yield and ultimate tensile strength.

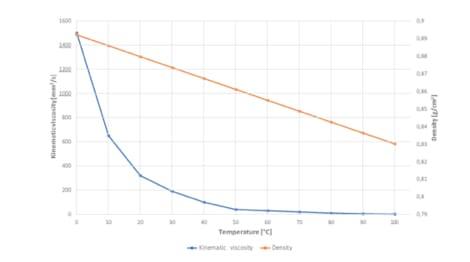

Product viscosity test

Through of a rotational viscometer, we can measure the viscosity of the products to be treated at different temperatures, in order to reconstruct the relative viscosity curve for each product as the ambient temperature changes.

Expected benefits

With the acquired data, laboratory tests are prepared in order to properly configure the filling terminal, to obtain maximum performance for the entire viscosity range of the products to fill.

Applications

Electronic weight fillers in lube field, edible oil and viscous liquids in general

Product viscosity test

Through of a rotational viscometer, we can measure the viscosity of the products to be treated at different temperatures, in order to reconstruct the relative viscosity curve for each product as the ambient temperature changes.

Expected benefits

With the acquired data, laboratory tests are prepared in order to properly configure the filling terminal, to obtain maximum performance for the entire viscosity range of the products to fill.

Applications

Electronic weight fillers in lube field, edible oil and viscous liquids in general.

Product specific weight test

The specific weight of the product is measured using a 100 ml pycnometer and a precision balance. This operation allows to establish the weight-volume correlation to the sample product, to determine the exact quantity of product (by weight) necessary to fill the desired volume.

Expected benefits

For high value products the correct calibration of the load cells and the repetitiveness of the filling precision (standard deviation) guarantees to the customer a considerable saving. OCME weight fillers can be certified as measuring instruments according to MID / OIML standards. This option results in further savings for the customer as it avoids installing a weight control on the machine.

Applications

Electronic weight fillers in lube field, edible oil and viscous liquids in general.

We make our great experience available to everyone: we organise trainings every day at our customers’ facilities to explain the importance of an AD HOC studied packaging, analysing all economic advantages both during the production phase and then during the transport.

Contacts