CERAMIC

Find out how the solution offered by Techlab to a customer in the world of ceramics resulted in a saving of 50% of consumables, increasing the stability of the packaging and reducing the risk of damaged products.

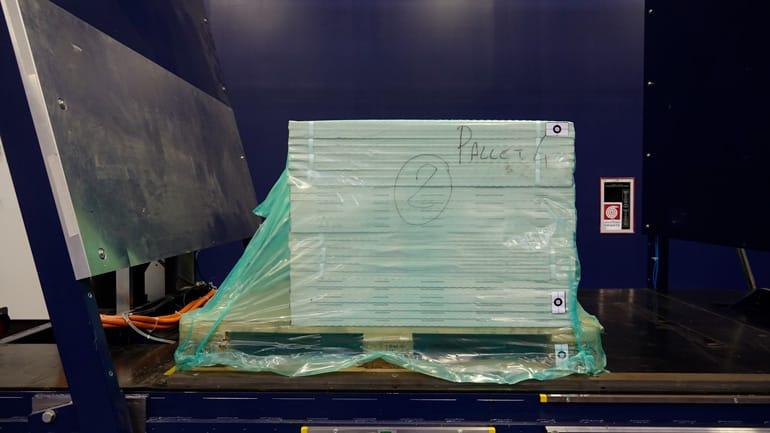

Currently in the world of ceramics most companies use the same method to pack their products: horizontal and vertical plastic strapping with the addition of a heat-shrinkable plastic cap.

However, this methodology leads to some difficulties in managing these products:

- use of different coils: according to the size of the pallet, we have to use a coil of suitable size;

- packaging difficulties: during the heat shrinking step, if the plastic material hits a sharp edge it can be pierced leaving part of the product uncovered;

- packaging fragility: once we go beyond the maximum sealing point, the packaging can break and the product could move freely and not be able to get stocked properly;

- high use of consumables: the plastic cap used for this type of product must be thick, because the load unit requires high protection and it is not possible to apply different amounts of film according to the needs of the pallet, but it’s applied the same amount all over the pallet.

Although the innovation in the world of shrink films has improved, we preferred to offer innovative solutions using a pre-stretch film that brings with it significant improvements for the ceramic field.

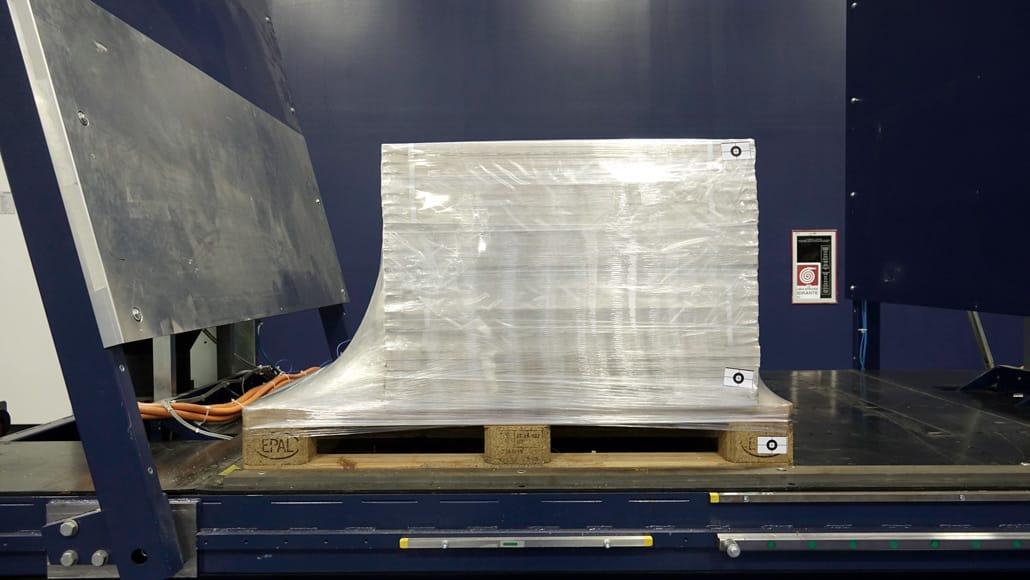

- Packaging versatility: with the same coil size it is possible to wrap all products.

- Characterisation of the wrapping: it is possible to apply different characteristics to each pallet according to its needs just changing the panel parameters.

- Resistance: one of the strengths of the pre-stretch of this product is certainly the ability to resist to sharp edges and at the same time provide a high resistance to stress due to transport, without showing damage.

- Limited use of material: thanks to the customization of the wrapping, it is possible to drastically reduce the use of film, while increasing stability.

- Guaranteed seal: thanks to the great seal of the film, it is possible to remove or replace plastic straps.

Thanks to the solution proposed to the customer, it was possible to reduce the use of consumables of 50%, while increasing the stability of the products and reducing the risk of damaged products due to transport or storage outside. With the pre-stretch film it was possible to reduce the presence of plastic straps, providing an equal or greater seal. The removal of strapping reduced the machinery present in the plant, having more space available and reducing the necessary maintenance

Contacts